Make your mobile chargers safer and more efficient than your competitors

You’re probably here because you just venture into mobile chargers production and you need more than a trusted manufacturer to provide all support from A to Z for a complete portable chargers procurement distribution chain.

You’ll be thrilled to have expert guidance every step of the way to ensure your investment is a resounding success.

You’re probably here because you are a senior buyer of mobile chargers, and you know the dynamics of this industry and the attributes of this kind of product very well.

You will be very surprised if a little of our professional advice can bring you a sudden new idea in your purchasing or marketing process.

You might have been sold a mobile charger that did not meet your expectations and in order to satisfy the sophisticated consumer market and stay constantly competitive, you urgently need a mobile charger that is more efficient, safer, and more practical than your competitors.

Either way, you are landing on the right page.

EverGreat is here to help.

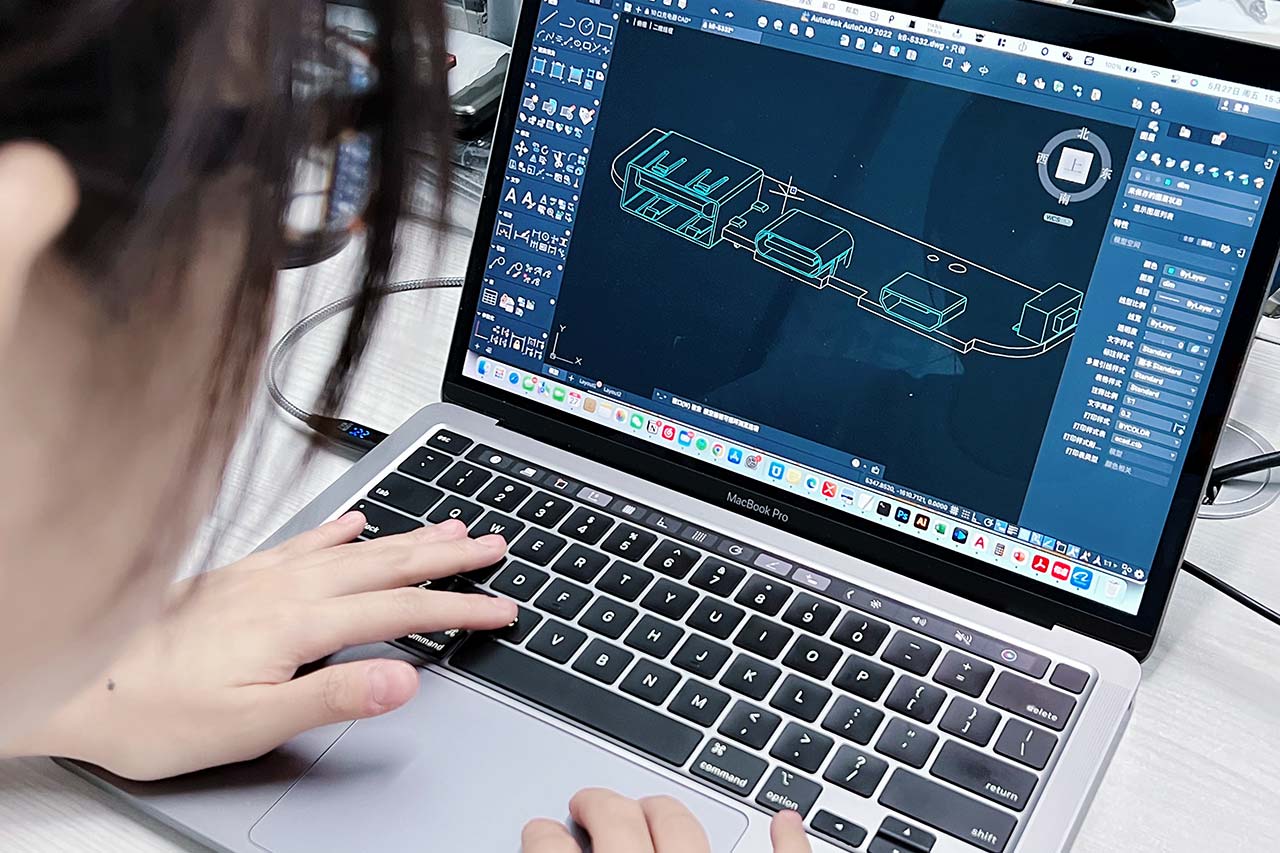

This initial phase involves detailed product design, including selecting the desired capacity (mAh), physical size and shape, and features like multiple charging ports, LED indicators, and fast charging technology. It also includes planning the production timeline, budget, and resource allocation.

Components such as lithium-ion battery cells, PCBs (Printed Circuit Boards), connectors, and casings are sourced from reputable suppliers. The choice of battery cells is crucial as it determines the power bank’s capacity and performance. Secondly, when these parts are all arrived, the incoming material inspection should be carried out.

This process includes the assembly of the battery, the assembly of the PCB and the final assembly of the whole charger.

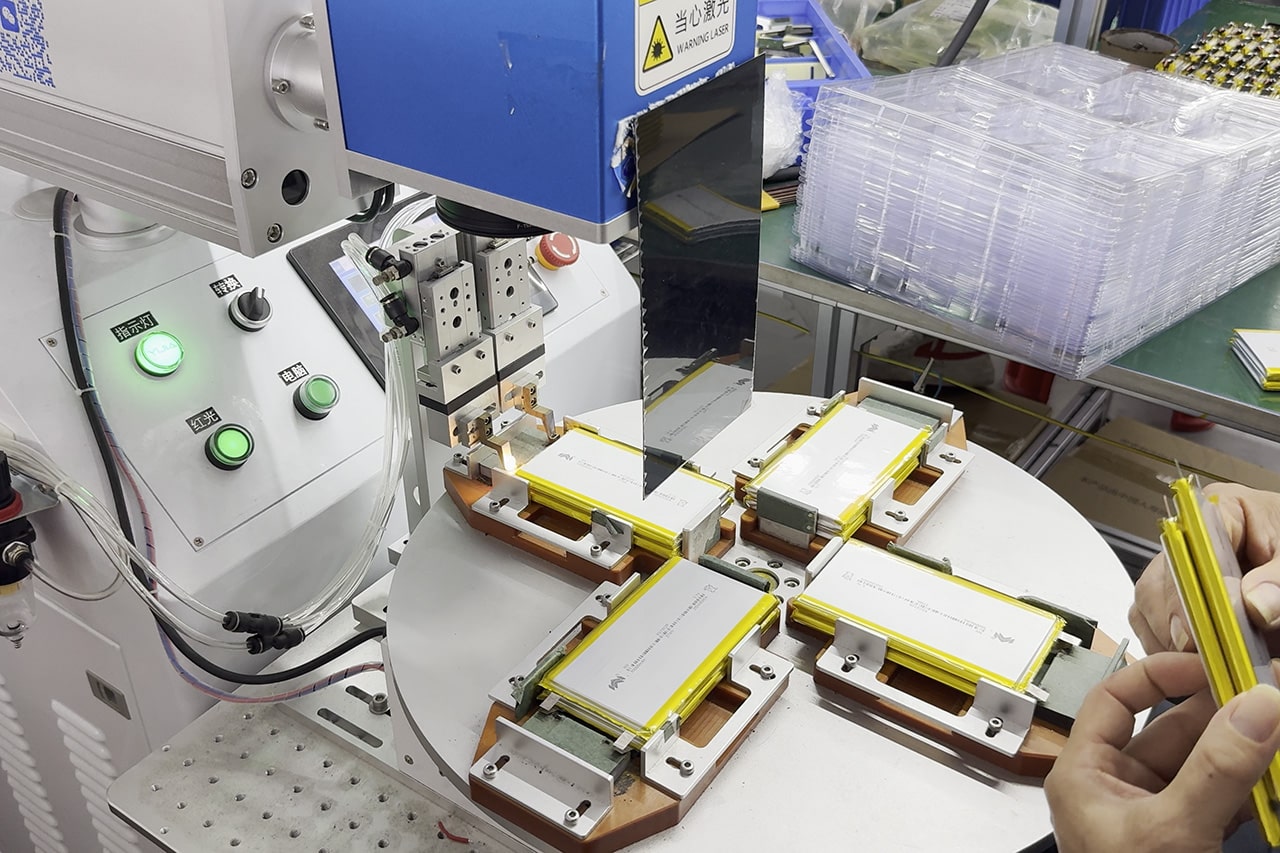

– Battery Assembly: Battery cells are grouped together and connected in series or parallel to achieve the desired voltage and capacity. Careful assembly and welding techniques are used to ensure electrical connections are secure and safe.

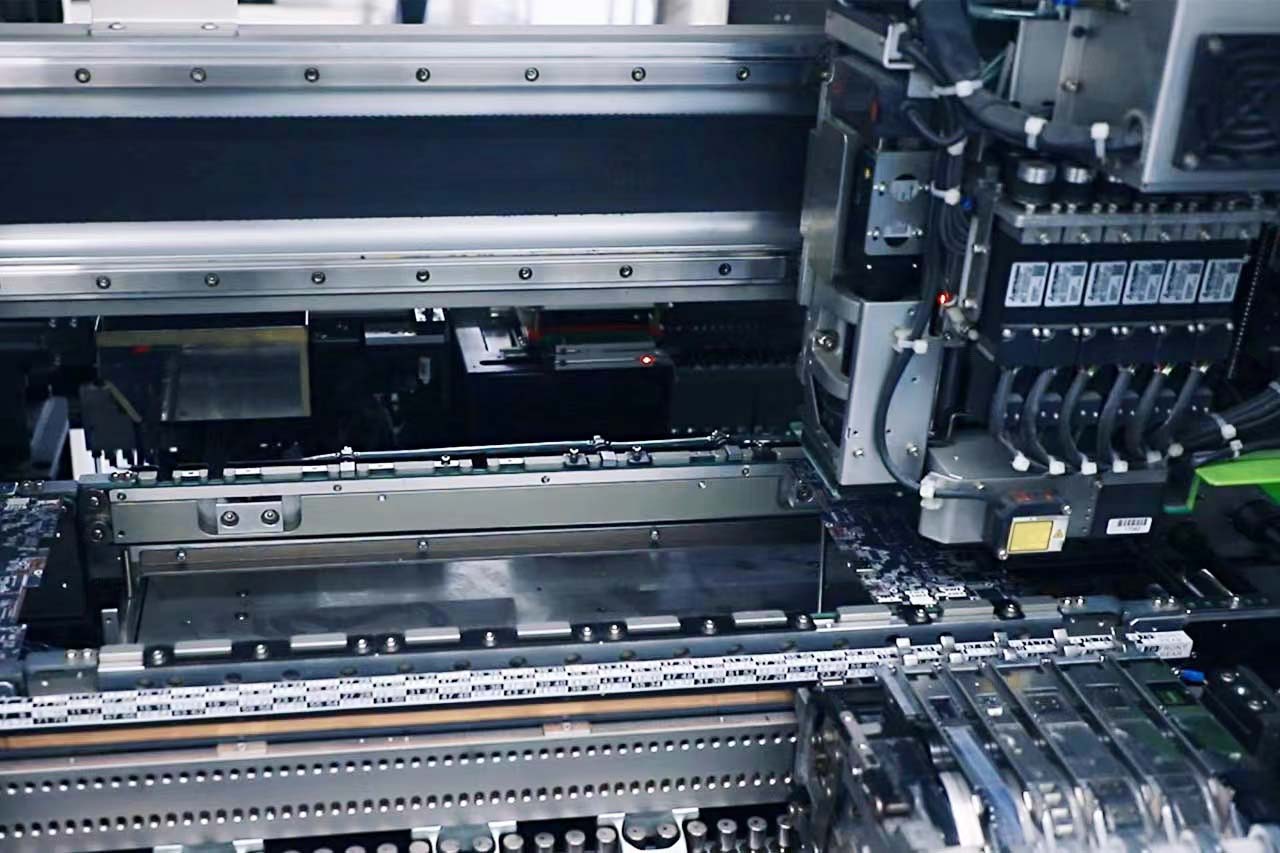

– Circuit Board Assembly: The PCB is designed and assembled to include components like charging and discharging control chips, voltage regulators, temperature sensors, and safety features like overcharge and over-discharge protection. Surface mount technology (SMT) is commonly used for PCB assembly.

– Finally, the battery pack and PCB are welded together by manual and machine, and then the shell is installed, and some special styles need to use glue or screws to fix.

The assembled products are then taken to for aging. In this process, the charger will be charged and discharged multiple times to ensure they can deliver the specified capacity without overheating or malfunctioning. This step verifies that the power bank performs as intended. After aging, we will also conduct manual checks to see if other functions are working properly. Finally, our quality inspection department will do a sampling inspection on the whole batch of products after testing.

Finished products are packaged with attention to detail, often in custom-designed boxes. Packaging includes adding user manuals, charging cables, and any accessories like carrying pouches or adapters. Then according to the customer’s requirements, into the corresponding carton, if necessary, we will also reinforce the packaging.

PCB Design

SMT Workshop

PCB Manufacturing

Battery Pre-Processing

Battery Pack Processing

Battery Capacity Grading

Mold Opening

Injection Molding

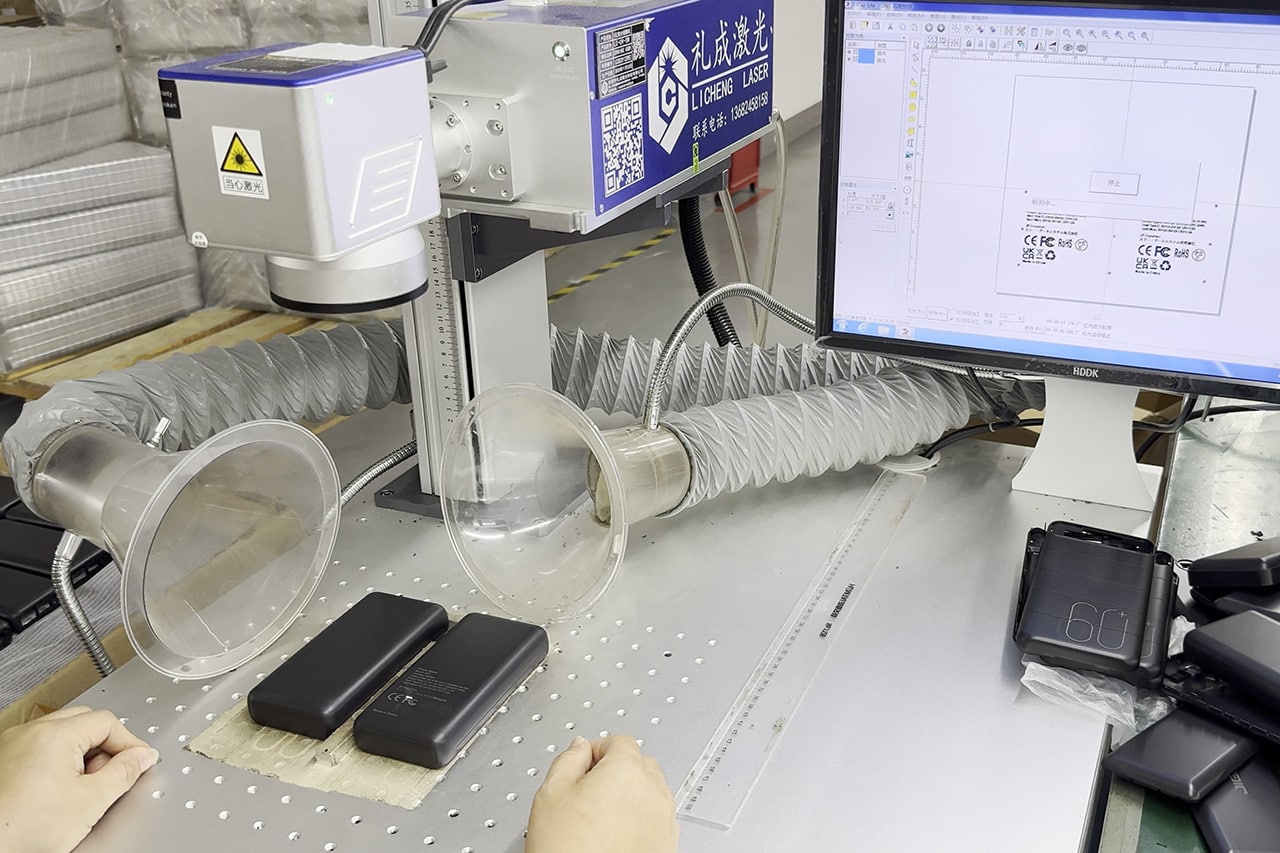

Laser-Engraved Logo

Product Testing

Aging Testing

Product Packing

Consumers in FMCG market are constantly searching for good quality products at competitive pricing. It is the same story with mobile charger products.

In this regards, the majority of mobile charger suppliers tend to compete on price to win over as more consumers as possible.

Every mobile charger supplier is trying to reduce their unit costs. They know pretty well that every penny they save is another penny they can use to defeat their competitors.

Yet apart from keeping their eyes on the mobile charger raw material supply chain, where should their attention go to cut down their portable chargers cost?

Speed/efficiency matters a lot to FMCG brands.

Instead of keeping their eyes on the initial purchase price, smart mobile charger supplier care more about how efficient a good mobile charger could be: If they can sell mobile chargers that are safer, last longer, and run more efficiently, they can sell more and more. By doing so, their unit cost could be significantly reduced.

Specific attention can be paid to the following aspects:

1. Battery capacity. There is a difference between actual and rated battery capacity.

2. Charging speed. Check whether the product uses the latest fast charge technology like QC3.1, PD, or proprietary fast charging protocols, etc.

3. Safety features. Ensure that the product has a comprehensive safety protection mechanism like overcharge, over-discharge, short-circuit, etc.

4. Certifications. Look for certifications as indicators of a well-made charger like CE, UL, FCC, RoHS, etc.

5. Warranty. A longer warranty period indicates the manufacturer’s confidence in their product.

In summary, Purchase high-quality products to minimize after-sales problems by reducing the frequency of replacement and repair. Spend more time on growing your business, which is maximum efficiency.

The consumer market is fast-changing. Especially the consumer electronics industry. The continuous updating of technology, the continuous iteration of the appearance and function of the product, and the different needs of consumers require us to “can not stop”.

In our contact with customers, some of the price-sensitive markets, need more cost-effective portable charging products; Some need more functional products to expand applicability; Some people need the help of innovative marketing programs to make them stand out from the competition.

In this case, you need a turn-key portable charger supplier that can provide you with as many services as possible, not just sell products.

This is where the EverGreat’s high-performance portable charger comes in.

We help you avoid the pitfalls of delivering the quality and value chargers need on time and on budget.

Building 703, Pengji Industrial Zone, Pengxing Road, Luohu District, Shenzhen, China

info@evgreat.com

Consult Your EverGreat Mobile Charger Experts

Our sales team has received your inquiry and will get back to you as soon as possible.

Our sales team will get back to you as soon as possible.