A COMPLETE PRODUCT MANUFACTURING PROCESS

What is a complete mobile chargers manufacturing process? – How are mobile chargers made?

A complete mobile chargers manufacturing process entails the following 5 steps:

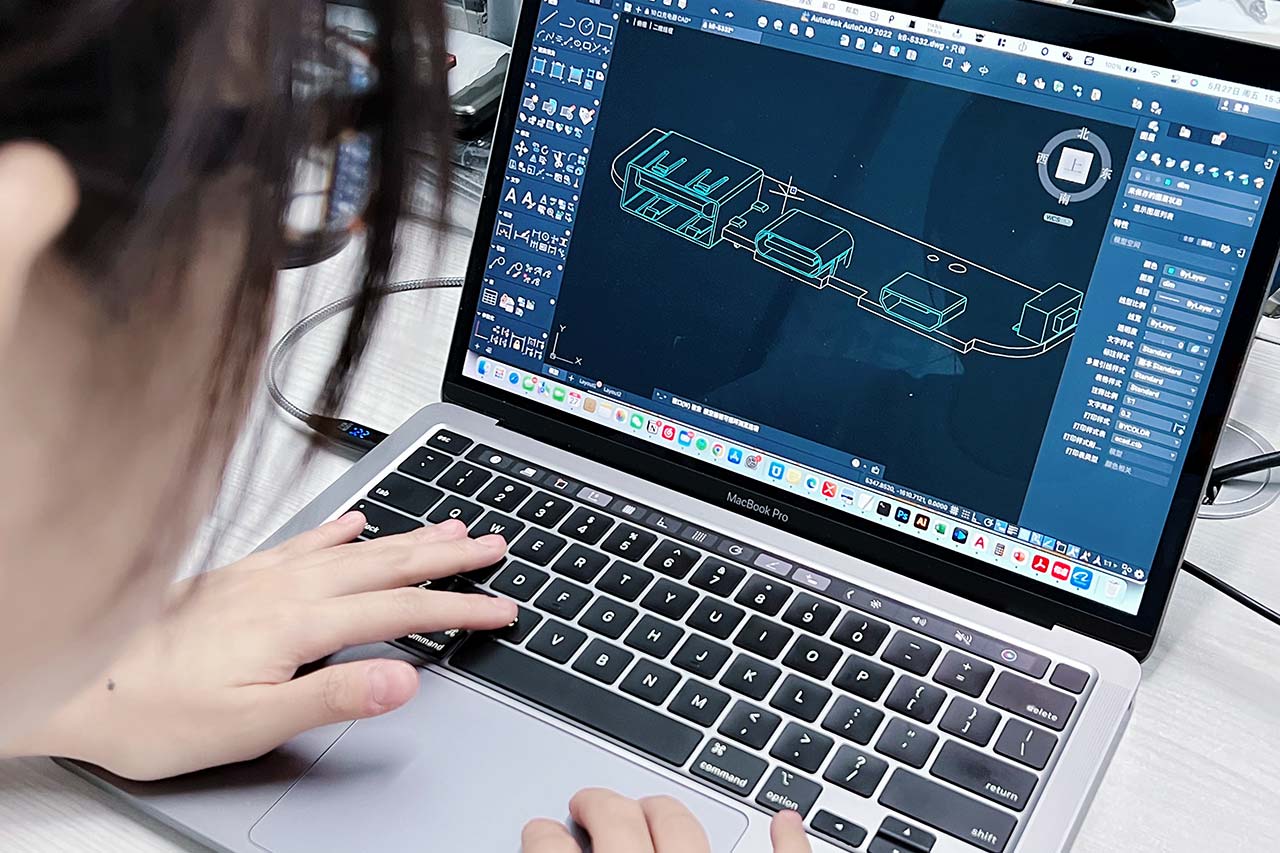

Step 1: Design Process

This initial phase involves detailed product design, including selecting the desired capacity (mAh), physical size and shape, and features like multiple charging ports, LED indicators, and fast charging technology. It also includes planning the production timeline, budget, and resource allocation.

Step 2: Core Components Preparation Process

Components such as lithium-ion battery cells, PCBs (Printed Circuit Boards), connectors, and casings are sourced from reputable suppliers. The choice of battery cells is crucial as it determines the power bank’s capacity and performance. Secondly, when these parts are all arrived, the incoming material inspection should be carried out.

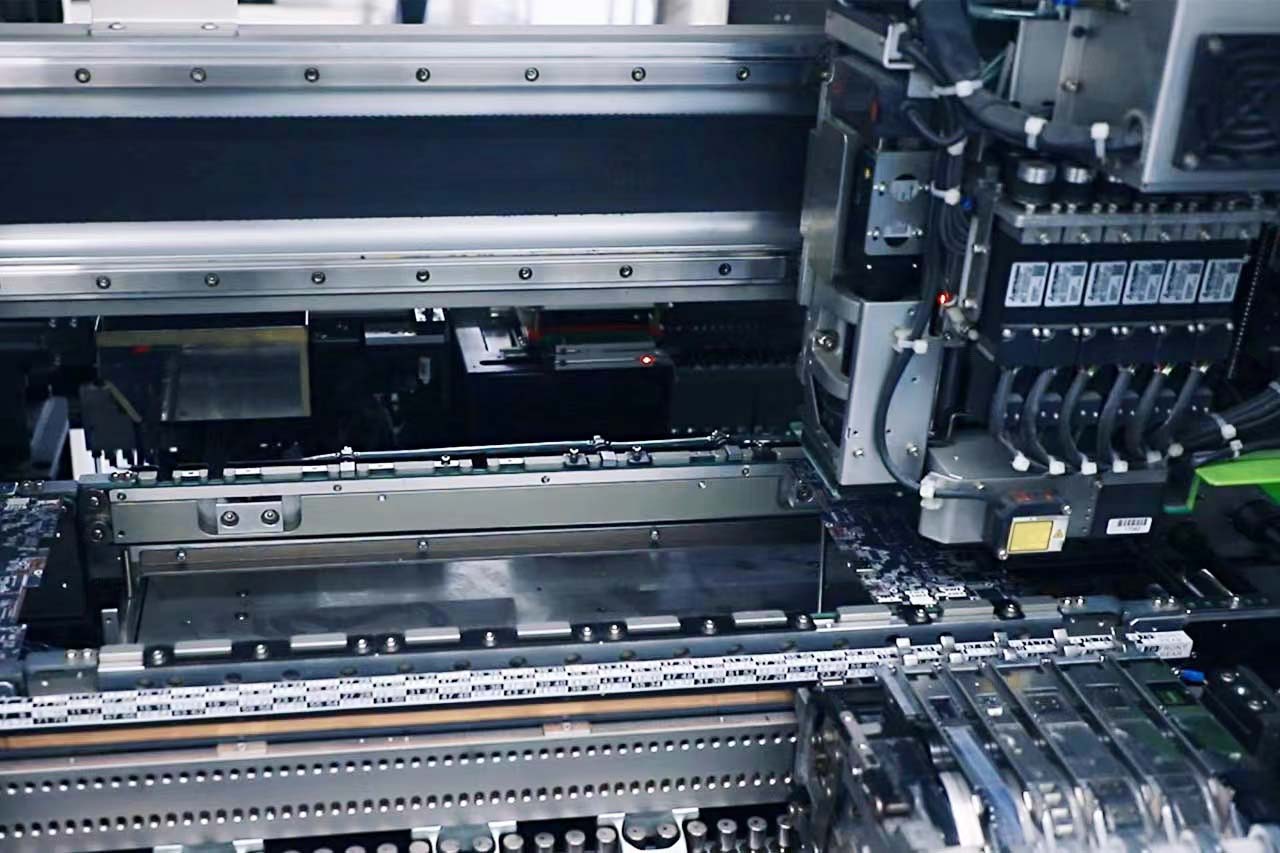

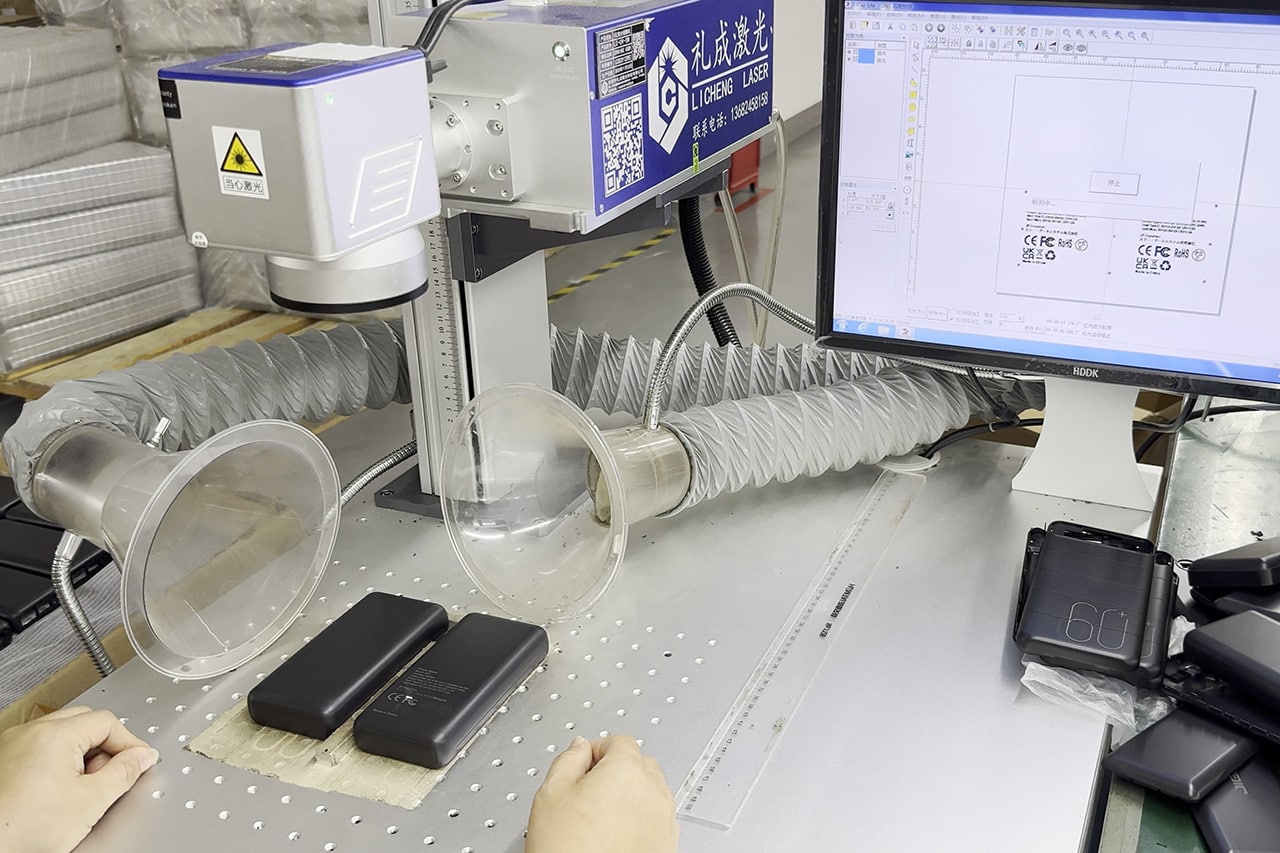

Step 3: Assembly Process

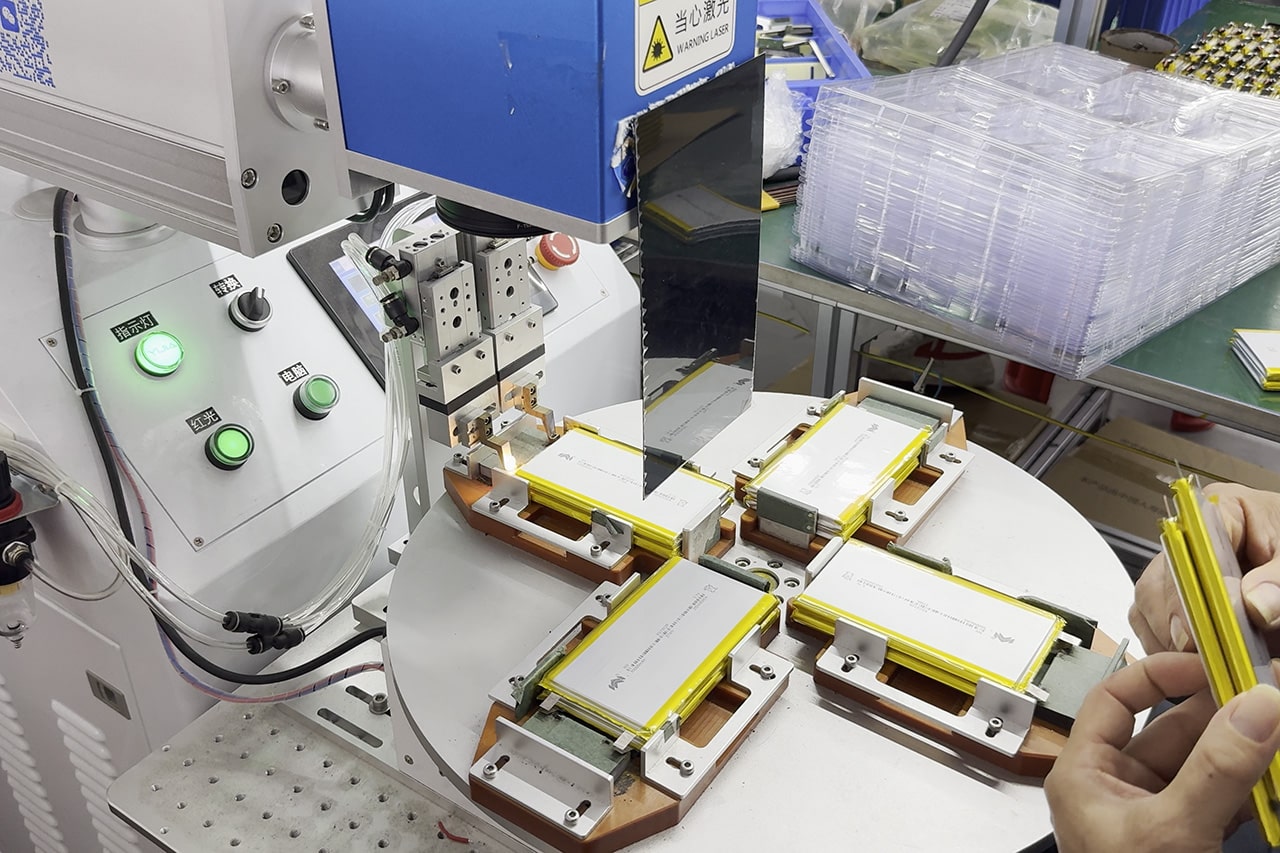

This process includes the assembly of the battery, the assembly of the PCB and the final assembly of the whole charger.

– Battery Assembly: Battery cells are grouped together and connected in series or parallel to achieve the desired voltage and capacity. Careful assembly and welding techniques are used to ensure electrical connections are secure and safe.

– Circuit Board Assembly: The PCB is designed and assembled to include components like charging and discharging control chips, voltage regulators, temperature sensors, and safety features like overcharge and over-discharge protection. Surface mount technology (SMT) is commonly used for PCB assembly.

– Finally, the battery pack and PCB are welded together by manual and machine, and then the shell is installed, and some special styles need to use glue or screws to fix.

Step 4: Testing Process

The assembled products are then taken to for aging. In this process, the charger will be charged and discharged multiple times to ensure they can deliver the specified capacity without overheating or malfunctioning. This step verifies that the power bank performs as intended. After aging, we will also conduct manual checks to see if other functions are working properly. Finally, our quality inspection department will do a sampling inspection on the whole batch of products after testing.

Step 5: Packaging Process

Finished products are packaged with attention to detail, often in custom-designed boxes. Packaging includes adding user manuals, charging cables, and any accessories like carrying pouches or adapters. Then according to the customer’s requirements, into the corresponding carton, if necessary, we will also reinforce the packaging.